![]()

New high-performance functionalised materials

SINGLE AND MULTIFILAMENT SPINNING OF YARNS WITH ELASTIC PROPERTIES FROM THERMOPLASTIC POLYMERS

TPELASTIC

Motivation

A significant percentage of textiles, in several applications, contain an elastic component that makes them suitable for certain roles: from fashion and sportswear to home textiles and medical fabrics, elastic confers enhanced performance in certain environments. Since its development, the most common is elastane (Lycra), offering excellent elasticity, which is inherently lacking in standard textiles, whether synthetic or natural. An addition of no more than one and three percent into the composition of a fabric greatly enhances its elasticity. However, the nature of elastane inhibits the ability to recycle the fabric, whether due to the difficulty of separating it from natural fibers, the impossibility of reprocessing it alongside synthetic materials, or removing it through chemical routes without damaging the material with which it is combined.

The growing concern for the sustainability of the textile sector and the drive to achieve a circular system in which pollution and environmental damage tends to zero has subjected the entirety of practices, processes, and materials used to exhaustive scrutiny, emphasizing alternatives capable of meeting the same needs while having a lesser impact on the environment.

Objectives

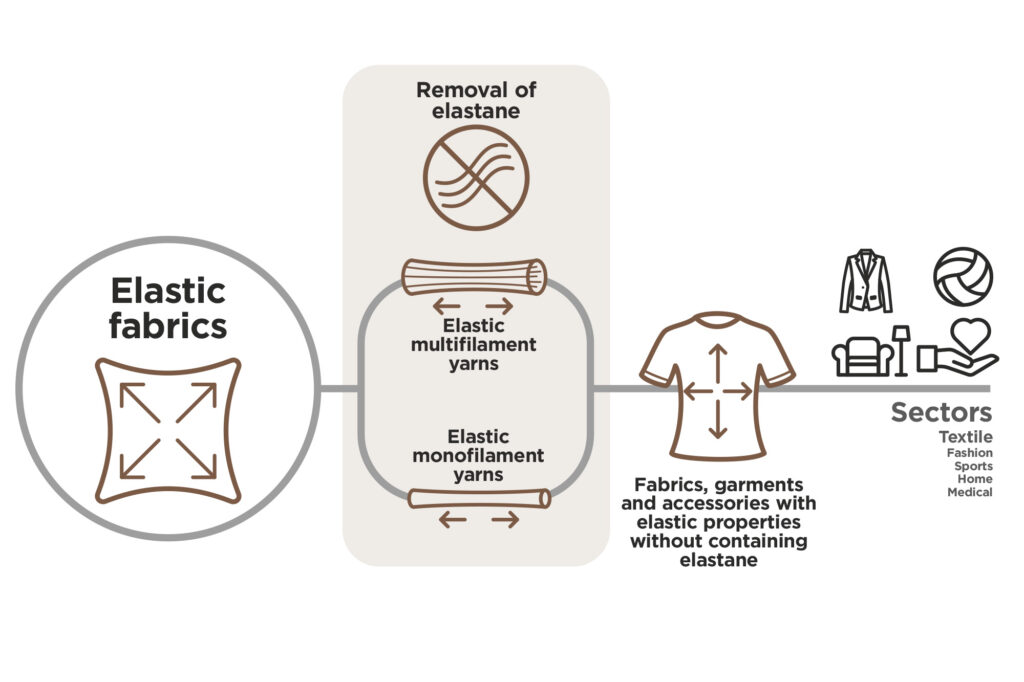

At present, there are no sufficiently mature and effective solutions that offer a viable alternative to elastane and it is in this context that TPELASTIC aims to replace elastane, using available technologies in the yarn production chain such as melt extrusion. This will greatly simplify its introduction and the possibilities for recycling and reuse will be much greater than those offered by elastane. TPELASTIC will have two branches similar in approach, which will involve specific aspects of the processes involved in obtaining elastic yarns and fabrics and respond to the issues presented by different applications.

The overall objective of TPELASTIC is develop and optimise mono and multifilament yarns with elastic properties from thermoplastic polymers by melt extrusion spinning, while considering more environmentally friendly materials such as biopolymers, biodegradable and compostable polymers, to eliminate the need to use elastane to create elasticity.

Expected results

- Achieve the production of mono and multifilament elastic threads based on thermoplastic polymers through melt extrusion spinning, addressing the need to introduce elastane, a less sustainable material, into fabrics.

- Use standard thermoplastic materials, such as PET and PA, facilitating their introduction into a widely established industry.

- Be able to process a wide variety of matrices that can be biodegraded or composted, without ruling out the possibility of being used alongside natural fibers.

- Improve the economic aspects for users of new elastic threads, as well as the producing companies, recycling companies, and thermoplastic polymer producers. This will be achieved through more efficient, accessible, flexible, and sustainable processes.

- Promote the creation, development, and implementation of products and materials aimed at achieving maximum waste reduction in the textile sector.

- Close the lifecycle of materials thanks to the possibility of reprocessing/recycling/reconverting textile waste with these materials, preventing most by-products or waste at any stage of the value chain from losing their utility.

Grant number: IMDEEA/2024/101

Programme: Grants to CV technology centres for R&D projects in cooperation with the private sector

Period of execution: January 2024 – June 2025

Status: In progress

More information: Amount – 176.040,58 €

Entity: IVAC

This project is supported by the Valencian Regional Government’s Ministry of Innovation, Industry, Trade and Tourism, through IVACE, and is co-financed by the FEDER (European Regional Development Fund) of the European Union, within the FEDER Operational Programme of the Valencian Community 2021-2027.

CONTACT US

Do you want to contact us? Click on the button and write to us.

R&D AREAS

NEWS

SAVE THE DATE! AITEX will host the 19th Textile ETP Annual Conference next year, from 13 to 14 May 2024 in AITEX headquarters, in Alcoy Alicante.

AITEX has attended the Cosmetorium fair in Barcelona once again on October to present its new products for the cosmetic sector.

AITEX analyses the problem of PFAS substances in various industrial sectors and presents various innovations to mitigate their presence in products and processes.