CHALLENGES

AND PROGRESS

IN THE REDUCTION

OF PFAS

An analysis of the problems posed by per- and polyfluoroalkyl substances (PFAS) in different industrial sectors, and innovations to mitigate their presence

Perfluoroalkylated and polyfluoroalkylated substances, also known as PFAS, are a group of chemical agents that include PFOA, PFOS, GenX.

PFAS are manufactured and used in a variety of industries around the world, as they are extremely tough and long-lasting and are commonly used in industrial and consumer products such as textiles, cosmetics and packaging, and this widespread use has led to their appearance in wastewater. Their excellent temperature stability and ability to repel water and grease have earned them the nickname “Forever Chemicals”.

In the textile sector, PFAS are used in oil and water repellent finishes, while in cosmetics, they are present in product formulations in their fluorinated or PTFE form. In addition, they are common components in detergents and packaging materials, reflecting their wide applicability. However, their ability to accumulate in the environment and our bodies has raised a number of public health concerns, linked to endocrine disruption, liver damage and specific cancers.

REGULATORY RESPONSES AND CONTROL MEASURES IN EACH ENFORCEMENT SECTOR

With growing evidence of their impact, the European Union has implemented stricter regulations to limit the presence of PFAS in consumer products

These include lowering the permitted limits and strengthening quality controls, ensuring greater protection for consumers and the environment.

In which industries can we find PFAS?

-

TEXTILES

-

COSMETICS

-

PACKAGING

-

WASTEWATER

studies over the last decade indicate high concentrations in a wide range of garments. They are used for their flame-retardant and water- and stain-repellent properties and are present in products ranging from underwear and swimwear to Personal Protective Equipment.

in cosmetics, PFAS are added to certain products to help condition and soften the skin, increasing glow and are used to alter the consistency and texture of a product, among other uses.

PFASs are used in packaging to prevent grease and water from leaching through food wrappers and beverage cups. PFASs can also be found in the ink used to print logos and instructions on food packaging.

PFAS can enter aquifers and water supply systems, contaminating our domestic water we use for drinking and food preparation. Continued exposure to these compounds has been linked to a number of health problems, highlighting the need to develop effective methods for their removal.

PFAS-FREE

SUSTAINABLE

ALTERNATIVES

THE ROLE OF AITEX IN THE DETECTION OF PFAS-FREE ALTERNATIVES

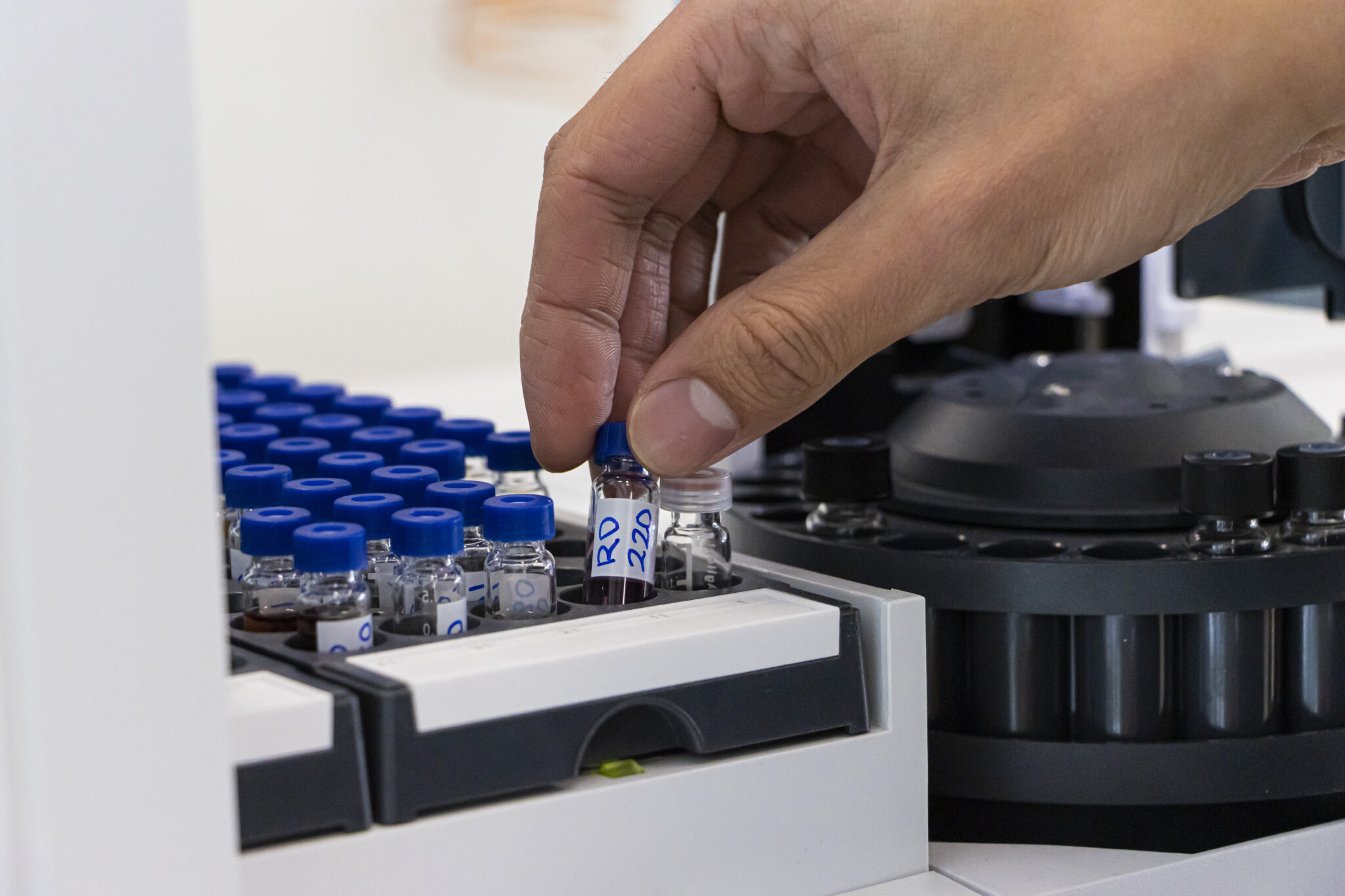

To ensure the efficacy of new formulations and the absence of PFAS, AITEX has introduced advanced chromatography technologies which can detect PFAS accurately and with great precision even at very low levels, aiding compliance with increasingly stringent regulations. These technologies are not only crucial to validate the safety of textile and cosmetic products, but also play a key role in environmental monitoring, helping to identify and quantify PFAS in wastewater and other packaging.

In addition to quantifying PFAS in products, AITEX is also engaged in the reformulation of finishes and coatings. As PFAS are becoming increasingly important due to their widespread use in the textile and leather industry, the threat they pose to health and the environment, and to comply with future US restrictions, AITEX and OEKO-TEX® certification have launched the Total Fluorine test.

The test determines the total fluoride content of a sample independently of the fluorinated compound from which it originates. Since the existing list of PFAS includes many different compounds, by analysing the total fluoride, all those not initially covered are now included.

The approach involves adjusting or modifying compositions to minimise the use of fluorocarbon-based compounds to avoid exceeding the 100 ppm total fluorine threshold, as now required by OEKO-TEX® certification. AITEX is the only Spanish centre approved to award this world-leading certification. The combination of additives such as dendrimers and waxes with advanced cross-linking techniques can reduce reliance on PFAS without compromising the quality and efficacy of a product.

In addition, AITEX is working on the development of fluorocarbon-free textile coatings that offer the same performance. Through collaboration in European research projects, AITEX is trialling formulations using modified polymers and natural waxes, seeking to replicate the water and oil repellent properties traditionally offered by PFAS. These alternatives, although still at the prototype stage, promise comparable functionality without the environmental and health risks associated with fluorocarbons.

REQUEST MORE

INFORMATION

If you wish to receive more information, please fill in and send the form, and we will contact you.

COMMITMENT TO SUSTAINABILITY AND INNOVATION

The PFAS issue is a multidimensional challenge that affects many industrial sectors. Collaboration between researchers, regulators and industry is essential to move towards effective solutions to reduce their impact.

This integrated approach aims to provide viable and sustainable alternatives, such as PFAS-free coatings, developed in collaboration with European research projects. Our commitment is clearly seen through a series of innovations and mitigation strategies focused on the substitution of these compounds and improved detection and removal methods.