![]()

New high-performance and functionalized materials

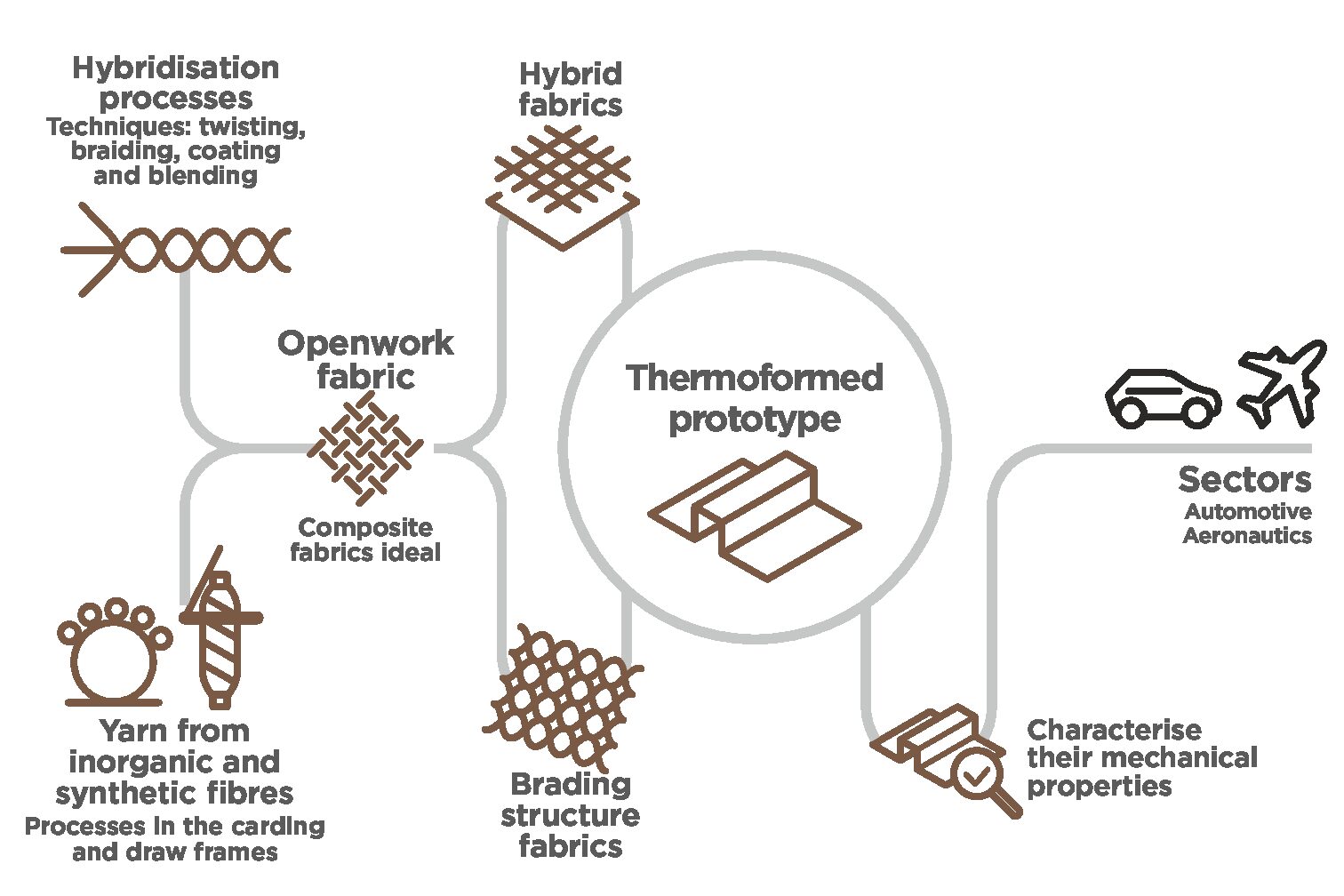

R&D of textile structures using recycled high added-value inorganic technical fibres.

FRINTEX

Motivations

The global market for composite materials has a volume of 17.7 million tonnes, valued at $86 billion. China and North America are the largest markets (28% and 26% respectively), followed by Europe (21%) and the rest of Asia (19%).

The increase in the use of composites has led to improvements in their physical and mechanical properties. However, the exponential increase in production has dramatically increased the amount of waste generated, posing serious environmental problems.

The FRINTEX project focuses on this problem by trying to reuse the waste by developing new products from it. Through reuse, the project will promote the circular economy by giving a second life to waste by producing new products while reducing the waste of raw materials used in the final product.

Objectives

The core objective of the project is to create prototype complex parts by thermoforming and characterise their mechanical properties. These parts will be manufactured from recycled inorganic fibres and synthetic fibres and their mechanical characteristics will be compared.

Value and competitive advantage

-

Given the complexity of obtaining high-quality recycled inorganic fibers for producing optimal hybrid threads and fabrics for composite development, the project’s focus has been redirected toward obtaining new types of hybridization for the generation of thermoformed products.

-

The hybrid weaving achieved is satisfactory using the two types of manufactured threads, allowing for the direct production of thermoformed products without the need for additional material resources.

-

The production of thermoformed products has enabled the creation of demonstrators that have validated the quality of the hybrid textile structures developed.

Results obtained

-

Generation of composite structures for the manufacture of composites from hybrid threads using various technologies.

-

The use of hybrid weaving with manufactured threads shows that the final finish is improved with the use of braided thread types. Using these fabrics, it is possible to obtain thermoformed products directly without the need for additional material resources.

-

The production of thermoformed products has enabled the creation of demonstrators that have validated the quality of the hybrid textile structures developed during the project.

Grant number: IMAMCA/2023/6

Programme: Plan of non-economic activities 2023

Period of execution: January 2023 – December 2023

Status: Finished

More information: PLAN OF ACTION

Entity: IVACE

This project is funded by the Conselleria d’Economia Sostenible, Sectors Productius, Comerç i Treball de la Generalitat Valenciana, through IVACE.

CONTACTE CON NOSOTROS

¿Quiere contactar con nosotros? Pinche en el botón y escríbanos.

ÁREAS DE I+D

NOTICIAS

SAVE THE DATE! AITEX will host the 19th Textile ETP Annual Conference next year, from 13 to 14 May 2024 in AITEX headquarters, in Alcoy Alicante.

AITEX has attended the Cosmetorium fair in Barcelona once again on October to present its new products for the cosmetic sector.

AITEX analyses the problem of PFAS substances in various industrial sectors and presents various innovations to mitigate their presence in products and processes.