![]()

New high-performance and functionalized materials

REVALORISATION OF TECHNICAL AND NATURAL FIBERS BY STAPLE FIBRE SPINNING PROCESSES APPLIED TO THE NAMUFACTURE OF THERMOPLASTIC COMPOSITES

REFICOM

Motivations

The long history of the use of composites in multiple applications means that there is a growing need for revaluation and reuse techniques for this type of material when it reaches the end of its useful life.

In many cases, the current state of the art in composites recycling is still far from the level of maturity of the recycling of other types of materials. For this reason, there is a growing need to develop revaluation methods and processes that allow these materials to enter the circular economy.

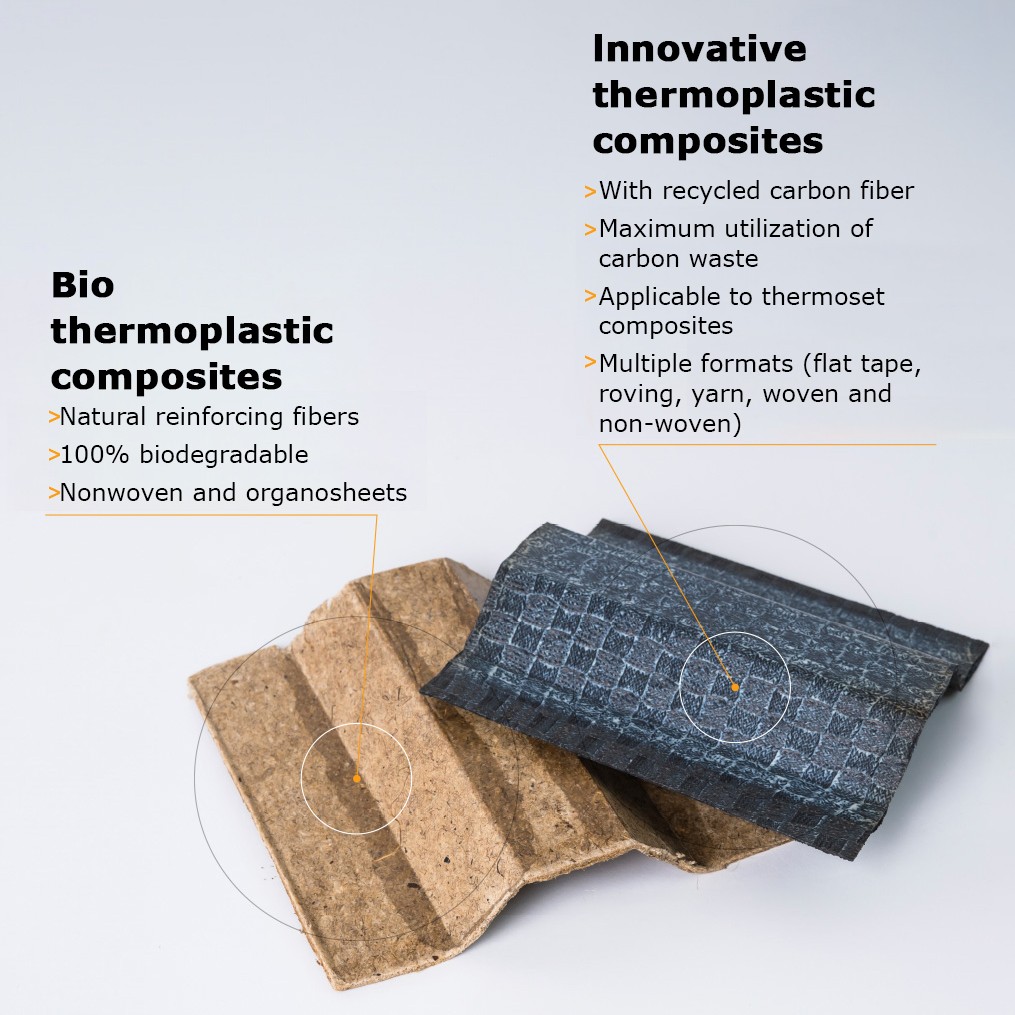

The REFICOM project aims to consolidate the development started in previous projects with the objective of making this type of materials industrially viable in terms of their mechanical properties. In addition, it may represent a very important step forward in the face of a growing problem, by proposing a possible way forward in the field of the reuse of composite materials.

Objectives

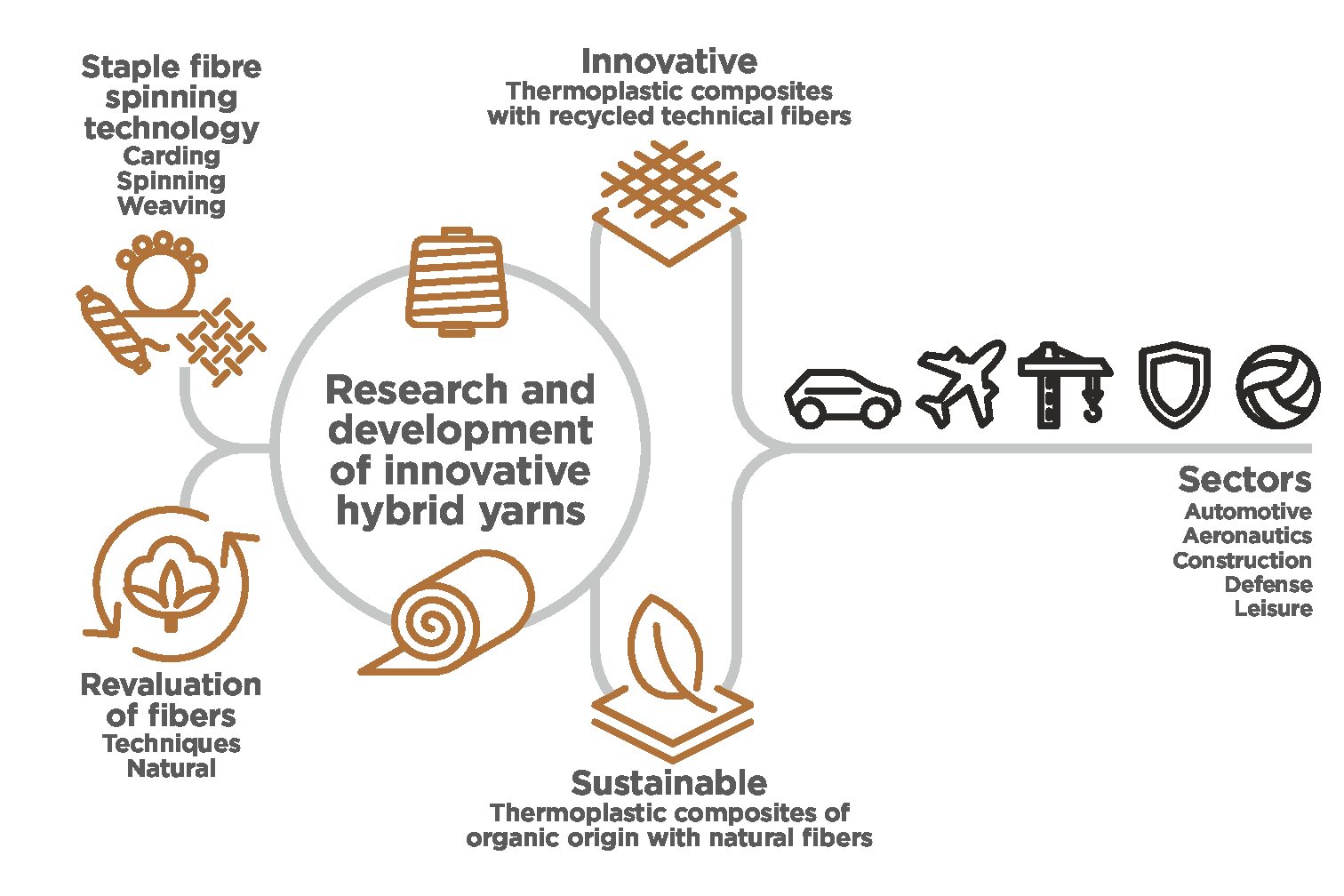

The core objective of the REFICOM project is the consolidation of staple fibre spinning technology (opening-mixing, carding, refining, tape doubling and spinning) applied to the revaluation of recycled technical fibres and fibres of natural origin that act as reinforcement in the production of thermoplastic composites.

In order to achieve the above objective in the framework of the REFICOM project, the following specific objectives are proposed:

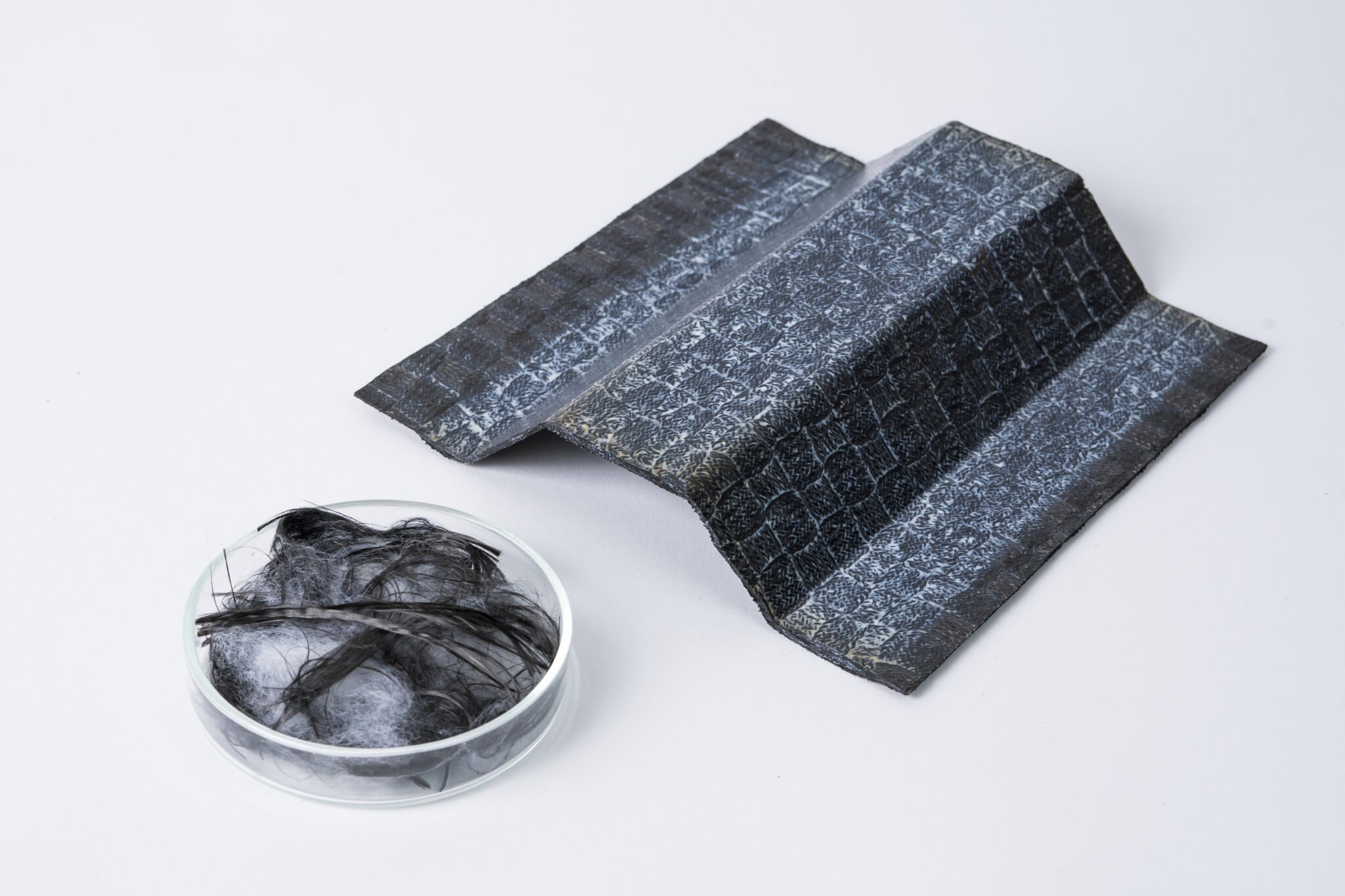

- Optimisation of the process of opening, mixing and sheathing of recycled technical fibres (rCF, rGF, rAramide, etc.).

- Research and development of innovative hybrid yarns with recycled reinforcement fibres and high performance technical polymers.

- Research and development of sustainable hybrid yarns with natural reinforcement fibres and bio-based polymers.

- Research and development of textile intermediates suitable for thermoforming processes.

Value and competitive advantage

-

The research conducted in the field of revalorizing inorganic fibers offers a different solution compared to existing studies focused on non-wovens or filaments for 3D printing.

-

This creates a very attractive business alternative for industries within the textile supply chain, as they use familiar technologies that, with certain modifications, would be perfectly suitable for revalorizing various types of fibers.

-

It also provides a promising alternative for companies that generate waste and wish to reuse it, transitioning from a linear system to a circular one in which the primary beneficiary is the environment.

Results obtained

-

Optimization and enhancement of fiber utilization, based on improving the processes involved in the stages of opening and mixing, carding, refining, spinning, and weaving.

-

Application of familiar technologies, which, with certain modifications, would be suitable for revalorizing various types of fibers.

-

An alternative for companies that generate waste and wish to reuse it, shifting from a linear system to a circular one, where the primary beneficiary is the environment.

Grant number: IMAMCA/2023/6

Programme: Plan of non-economic activities 2023

Period of execution: January 2023 – December 2023

Status: Finished

More information: PLAN OF ACTION

Entity: IVACE

This project is funded by the Conselleria d’Economia Sostenible, Sectors Productius, Comerç i Treball de la Generalitat Valenciana, through IVACE.

CONTACTE CON NOSOTROS

¿Quiere contactar con nosotros? Pinche en el botón y escríbanos.

ÁREAS DE I+D

NOTICIAS

SAVE THE DATE! AITEX will host the 19th Textile ETP Annual Conference next year, from 13 to 14 May 2024 in AITEX headquarters, in Alcoy Alicante.

AITEX has attended the Cosmetorium fair in Barcelona once again on October to present its new products for the cosmetic sector.

AITEX analyses the problem of PFAS substances in various industrial sectors and presents various innovations to mitigate their presence in products and processes.